Aquionics UV Equipment at Sierra Nevada Brewing

Aquionics UV Equipment has proven to be a valuable non-chemical solution to ensure product quality for the Sierra Nevada Brewing Company in North Carolina.

Nuvonic and Rodem provide non-chemical application for disinfection, ozone destruction, TOC reduction, and UV dichlorination.

UV technology within sanitary processing environments is an excellent way to conserve energy, lower operating costs and optimize efficiency. Our UV partner, Nuvonic has created a system that guarantees performance, reliability, simple UV management, accurate monitoring, and control.

Nuvonic is a leader in non-chemical, UV solutions to the food and beverage industry globally. They have a reputation for supplying state-of-the-art technology for disinfection, ozone destruction, TOC reduction, and UV dechlorination to some of the most recognized brand-name products in the industry.

Outbreaks of water-borne pathogens place producers at high risk of costly and damaging recalls and product liability. Nuvonic has led the way in pre-treatment disinfection and treating direct contact fluids and ingredients, CIP and bottle rinse, liquid sweeteners, meat brine, tank headspace, venting, packaging, and surfaces.

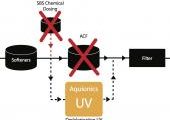

UV installed ahead of the RO unit for dechlorination provides a non-chemical form of water treatment that eliminates the need for activated carbon beds and the associated costs of maintaining and disposing of the spent carbon. A UV dechlorination system can also eliminate the need of a sodium metabisulfite system to remove the chlorine, thus protecting the RO membranes from microbial biofouling or sliming of the membranes due to poor metering of the chemical injection.

UV can be installed before the activated carbon bed to reduce the bio-burden from entering the carbon beds and thus extend the carbon’s life.

Carbon beds provide an ideal environment for microorganisms to grow rapidly, thus producing biological contamination. UV disinfection equipment installed just after the carbon bed provides a non-chemical form of water treatment that does not affect a product’s color, odor, taste, or pH. UV disinfection of carbon-filtered water has been an accepted application for decades now.

Ozone has been used in the food and beverage industry for many years as a disinfectant and sanitizer. While ozone has many benefits, it must be removed from the water stream so that it does not alter a product’s taste or composition. UV ozone destruction equipment is usually the product of choice for this process. Typical ozone destruction systems remove up to 1.0 ppm of dissolved ozone from the water stream in a single pass.

Material storage tanks require direct headspace protection as well as eliminating intrusion during drain and fill operations. Nuvonic provides two different models to disinfect the headspace at the top of the tank. The equipment simply mounts to existing vent holes and provides up to one year of quality control before the UV lamp needs to be replaced.

Even water used to clean surfaces or used in CIP operations can be a source of contamination. UV is an approved method of reducing bacteria without the use of chemicals.

Traditional sucrose-based sweeteners provided an ideal breeding ground for microorganisms. UV was, and still is, used to treat simple syrups and reduce the need for pasteurization. With the food and beverage industry now moving away from HFCS products, there is a real challenge with heat-resistant molds and yeasts that must be addressed, especially with more unrefined inverts coming to market. Today’s medium-pressure UV systems can provide a 3.5 log reduction of heat-resistant molds to the most challenging sucrose products.

Process plant effluents can be treated without the use of environmentally hazardous chemicals. Nuvonic offers both pressurized and gravity flow systems to treat your industrial waste streams.

Many foods are subject to contamination after heat treatment or cooking. UV provides an excellent method to protect foods from contact cooling fluid contamination such as brines and marinades. Nuvonic’s UV systems are specifically designed to provide a 5-log reduction of Listeria in the low transmission values of the brines and marinades at the very cold temperatures.

Pre-Treatment Disinfection

Cooling Media (Brine, Chillers, etc.)

Direct Contact Fluids and Ingredients

CIP, Bottle Rinse or Wash Waters

Liquid Sweeteners and inverted sucrose

Tank Headspace and Venting

Water as an ingredient in a food or coming in direct contact with food can be a source of contamination. UV can disinfect this water without chemicals or pasteurization.

There are three distinct types of UV lamps. These are characterized by the mercury vapor pressure inside the lamp, and the relative UV energy they produce:

Rodem specialized in custom sanitary process fabrications and solutions. Discuss your full project needs with a Rodem team member to see how we can help you build the exact system you need.

Aquionics UV Equipment has proven to be a valuable non-chemical solution to ensure product quality for the Sierra Nevada Brewing Company in North Carolina.

Aquionics UV dechlorination technology provides distinct advantages over traditional technologies like Activated Carbon Filter. Check out all the benefits!

When a pharmaceutical producer required an alternate way to sterilize water for their processes, they found the solution and additional savings in an Aquionics UV unit

Heard the buzz about using UV in your plant for disinfection? Learn more about how you can truly put UV to work in your plant with the facts.

When an international beverage manufacturer was faced with meeting new standards for disinfecting incoming water for production, they found the answer in a new Aquionics PQ 1100, UV Transmittance Monitor and UV Connect.

Viruses and bacteria threaten consumers’ health and harm the taste, shelf-life, and color of food. Compared to chemical methods, UV disinfection from Aquionics requires little effort and does little damage to the environment.

E-mail: [email protected]

Copyright 2024 Rodem Inc. All rights reserved.