Home > Process Solutions > Skid Systems

Since our inception in 1971, Rodem has helped clients realize the benefits of prefabricated, modular assemblies and manufacturing components for the sanitary processing industry. Building these skidded systems in our fabrication shop minimizes facility and production disruption. Proper design and sanitary skid system installation for food, beverage, dairy, pharmaceutical, and other processors:

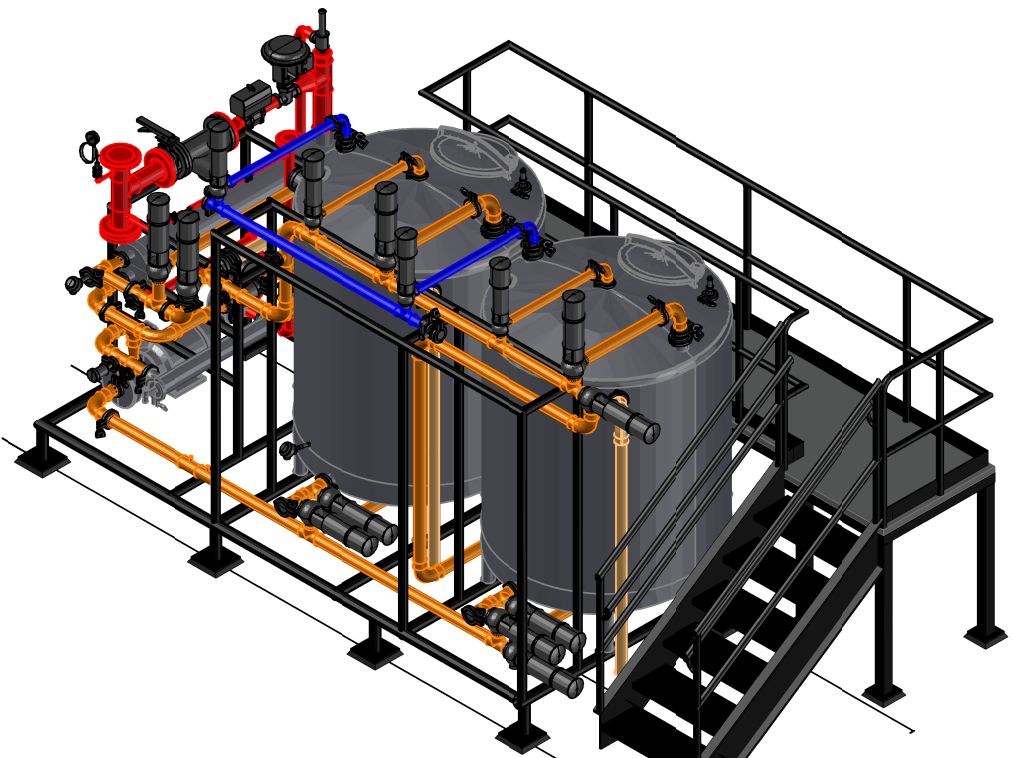

Rodem takes a strategic, collaborative approach to your skid system engineering, construction, and installation. We strategically design your skidded system and carefully select each piece of equipment, piping, framing, instrumentation, and any additional component you may need. We integrate with upstream and downstream processes to maximize your plant’s available space and optimize existing processes. With fabrication and assembly accomplished at Rodem s, we can efficiently integrate the entire sanitary skidded system into your facility drastically reducing set-up, testing, and start-up time and expense.

By focusing our scope to solely sanitary processing equipment and solutions, Rodem has gained unparalleled expertise in the needs of the food and beverage, pharmaceutical, dairy, personal care, and other sanitary processing industries. Whether you need skidded system solutions for clean-in-place, mixing and blending, heat exchange, filtration, separation, or any other process, Rodem offers proven engineering, fabrication, and installation solutions. Trust us to deliver time-sensitive and complex projects built to your specifications.

We pride ourselves in providing turnkey sanitary processing skid systems that can be implemented and brought online with few adaptations or customizations on your end.

Rodem’s engineers draw on decades of sanitary processing expertise and the most trusted equipment brands to deliver personalized skidded system solutions to the biggest name brands in the industry. Our team specializes in high-purity stainless steel orbital welding, which ensures consistent welds on each project. Rodem’s process engineering focuses on yield and throughput to ensure maximum productivity from your new skid system.

Learn more on our custom fabrication capabilities here.

We know that as manufacturers of the products that feed and heal America you cannot compromise on quality and safety. At the same time, we understand the importance of controlling costs wherever possible. Modular skid fabrication meets the demand for both. As a leading process skid manufacturer, Rodem delivers competitive advantages including:

We know that as manufacturers of the products that feed and heal America you cannot compromise on quality and safety. At the same time, we understand the importance of controlling costs wherever possible. Modular skid fabrication meets the demand for both. As a leading process skid manufacturer, Rodem delivers competitive advantages including:

Rodem’s skid system engineering, manufacturing, and installation capabilities can be utilized for a wide variety of sanitary processes.

Steam in place skid systems, or SIP are excellent options for food and beverage, pharmaceutical, and personal care industries. The SIP process involves circulating steam through process equipment and pipelines to remove any residual contaminants, ensuring that the equipment and piping are clean and sterile. A Steam-In-Place skid system is a compact, self-contained unit that is designed for easy installation and operation.

Mixing and blending skids are excellent turnkey options for food, beverage and other high purity processors. These compact, easy to install skidded systems offer a variety of solutions including continuous blending, high shear mixing, powder/liquid blending or emulsifying.

Filtration and separation skids provide an efficient and cost-effective solution for sanitary industries that require filtration and separation processes, as they are easy to install, operate, and maintain, and can be customized to meet specific requirements. The system is usually mounted on a skid, which provides a solid base for easy transportation and installation.

Other Rodem skid offerings include modular skid systems designed for:

Learn more about the wide variety of skid types Rodem offers and their intended uses.

Our team has vast experience with skid system design. Like all processes we design, our goal with these systems is to maximum efficiency and yield with world class sanitary design in mind. See more about our Sanitary Design and Process Engineering capabilities.

Our team has vast experience with skid system design. Like all processes we design, our goal with these systems is to maximum efficiency and yield with world class sanitary design in mind. See more about our Sanitary Design and Process Engineering capabilities.

Rodem becomes an extension of your in-house team and engineers to evaluate your resources and constraints and determine where a skid system assembly makes sense. With industry-leading technology, skillsets, and facilities, Rodem develops skid systems to your precise requirements. You can rest assured that the skid system we create for your facility will be installation ready. We won’t leave until we’re satisfied that the module meets your process and workflow needs, the system has been fully tested, and your operators and inspectors are comfortable using it.

Contact Rodem for a consultation about the advantages of our skid system engineering and manufacturing services when you face any of these challenges:

Speak with a Rodem representative to learn more about if a Skid System design is right for you by completing our Get a Consultation form:

E-mail: [email protected]

Copyright 2024 Rodem Inc. All rights reserved.