No Time for Downtime? Use Sani-Matic Dual Side Entry Strainer Assemblies

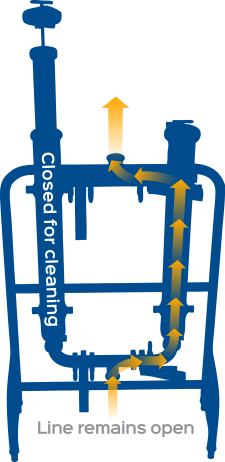

Although cleaning is a necessary part of processing, shutting down production to clean is expensive and inconvenient when production goals must be met. Dual side entry strainer assemblies allow plants to clean at high capacities and maintain constant production by shutting down one line for cleaning as the other line keeps the process moving. Dual side entry strainer assemblies from Sani-Matic are ideal solutions for food, beverage and pharmaceutical processors facing strict production demands and tight manufacturing schedules.

Top Four Reasons for Using Dual Side Entry Strainers

- You have frequent strainer cleaning requirements due to high particulate count.

- Your product quality is impacted by process interruptions.

- Your operation is capital intensive and downtime results in major financial consequences.

- You need to reduce inefficiencies associated with stopping and restarting a process.

The dual side entry strainer assembly keeps everything moving to increase production uptime and improve your bottom line, while also helping to maintain product integrity and protect costly processing equipment from damaging debris.

Selecting the Right Dual Side Entry Strainer Assembly for Your Process

There are a lot of factors that come into play when determining what dual strainer assembly is right for your process. The following are just some of those to consider:

- Product viscosity

- The percentage of solids you want to strain

- The size and shape of particles to be strained

- Whether 3-A certification is required

- Line sizes, flow rates and temperatures that can affect pressure drops

To explore dual side entry strainer assembly options from Sani-Matic and to see how they can help you increase uptime, speak to a Rodem rep today.