stop wasting product & money: liag laufer pigging systems and sustainable processing

In an era where resource conservation is imperative, our clients are constantly seeking innovative ways to minimize waste and maximize efficiency. LIAG offers hygienic pigging systems that not only recover valuable product but also contribute significantly to sustainability goals.

The Problem of Product Waste

In the food, beverage, personal care, and other high-purity industries, residual product left in pipes after processing is often flushed down the drain. This represents a significant loss of valuable resources and contributes to environmental pollution. But what if there was a way to recover nearly all of that product?

LIAG Pigging Systems: A Sustainable Solution

By using a “pig” to push residual product through pipes to its intended destination, these systems can recover up to 99% of high-value, viscous materials. This not only prevents product waste but also reduces the environmental impact associated with disposal.

Key Features and Sustainability Benefits

- 99% Product Recovery:

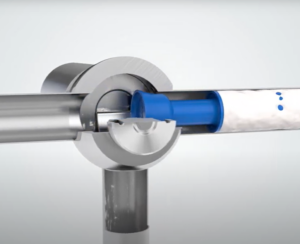

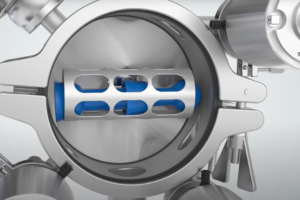

- LIAG’s uniquely designed DMV pigging system, with its 2-seal lip pig, ensures maximum product recovery, minimizing waste and maximizing yield.

- This means more product available for consumption, reducing the need for additional raw materials.

- Reduced Water Consumption:

- By recovering product before cleaning, pigging systems significantly reduce the amount of water required for flushing and cleaning.

- This directly translates to water conservation, a critical aspect of sustainable operations.

- Minimized Waste and Environmental Impact:

- Preventing product from being flushed down the drain reduces the burden on wastewater treatment systems and minimizes environmental pollution.

- Less product waste also means less waste sent to landfills.

- Improved Cleaning Efficiency:

- Pigging systems streamline the cleaning process, reducing cleaning times and increasing overall efficiency.

- Faster cleanings mean less downtime, and less chemical usage for CIP systems.

- Cost Savings:

- Recovering valuable product translates to significant cost savings, improving your bottom line.

- Reduced water and chemical usage also contribute to lower operating costs.

- Dynamic Seal Technology:

- LIAG’s dynamic seal pig design eliminates product dilution and contamination, ensuring product integrity.

- The design also allows the pig to navigate tight pipe bends.

- Hygienic Design:

- LIAG pigging systems are designed with hygiene as a top priority, ensuring compliance with strict sanitary standards.

Why This Matters to Your Business

Implementing LIAG pigging systems can help your business:

Implementing LIAG pigging systems can help your business:

- Achieve significant cost savings through product recovery and reduced waste.

- Enhance your sustainability efforts and demonstrate a commitment to environmental responsibility.

- Improve operational efficiency and increase productivity.

- Maintain product integrity and comply with sanitary standards.

Partner with Rodem for Sustainable Solutions

At Rodem, we’re committed to helping our customers achieve their sustainability goals. LIAG pigging systems are a powerful tool for minimizing waste and maximizing efficiency.

Interested in learning more about hygienic pigging systems and if they’re the right solution for your application?

Learn more about LIAG Laufer Pigging Systems here.