Menu

Hygienic pigging systems for food, beverage, and personal care product processes are an environmentally conscious way of streamlining production, reducing cleaning time, slashing water use, and minimizing product loss. Adding a hygienic pigging system to your sanitary process is fairly straightforward in comparison to other system modifications, but there are some key factors to include as you consider pigging procedures and design your system. From defining system goals to adding considerations for piggable valves and smooth bore welds, count on Rodem to help navigate the building of your pigging system.

As with all projects, clearly defined scopes and requirements will lead to a more successful implementation. The benefits of hygienic pigging systems are plentiful, so be sure to define your objectives beyond the obvious goal of maximum product recovery. Whether your main goal is to minimize environmental impact or reduce cleaning time, clear objectives will yield positive system design and installation.

Learn more about the benefits and types of Hygienic Pigging Systems.

Our team uses a data collection template to gather information to help spec out pigging system options. The template collects information such as:

It’s also important to communicate the current cleaning procedures, product sources, and changeover frequency to your pigging system provider.

Our hygienic pigging system partner, LIAG®, also requests that all processors submit a flow scheme for process and piping, as this can affect the components used. Harsh processing conditions, dimensions, and materials of your piping will directly impact your pigging procedure and system. Be sure to take the details of the process into consideration as you work with a pigging process partner to design a system that works for your process.

When documenting your existing piping and system, take special consideration to examine your welds, pipe, and equipment for crevices, dents, and damage. Welds and piping must be smooth internally to prevent damage to the hygienic pigging system and ensure proper performance.

Using hygienic piggable valves in your process also helps ensure an effective pigging system. LIAG® arc valves and LIAG® pig diverter valves have been designed according to hygienic design guidelines (3A) to meet the high demands of process engineering applications, ensure a high hygienic standard, and most importantly, are piggable. More piggable valves present in your process system means that you are able to pig a longer line, recover even more product, and increase your ROI year after year.

Arc valves are particularly suited for viscous/pasty products on account of a totally clear passage as well as an easy and thorough cleaning in place. As a result, they provide optimum conditions for a wide variety of low germ/sterile pigging processes, such as the DMV pigging system.

By virtue of their simplicity of design and their minimum number of components and wearing parts, arc valves are characterized by a high hygienic standard, low and infrequent maintenance, and easy dismantling even when welded in place. Thread and clamp unions are virtually no longer needed, thus eliminating hygienic risks from the very outset. Consider LIAG® hygienic piggable valves to be a part of your pigging procedure.

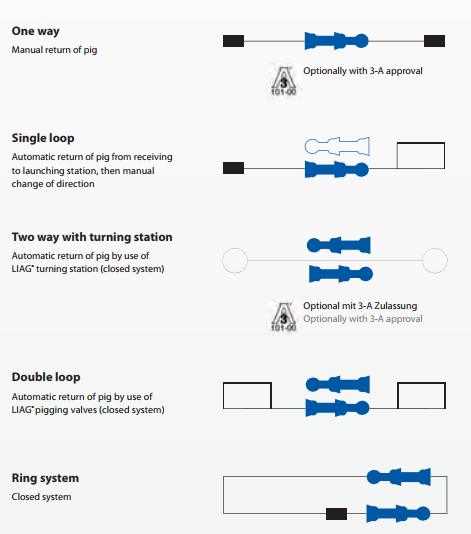

Optimum pigging geometry and a suitable process depend on different process factors and are therefore always designed to the specific project. The particular components are dependent on your pigging procedure needs and specifications. The below diagram shows the different types of configurations and the necessary components to build each particular system.

In each LIAG® DMV pigging system, the product is pushed by a dynamic 2-seal lip pig. DMV lip pigs are of homogeneous construction and hygienic design. They offer excellent cleaning effects, are virtually free of wear, and the dynamic lips form a reliable seal. As a function of the pressure from the pushing medium and counterpressure from the product, these dynamic lips accommodate perfectly, thereby compensating existing deviations in the pipe geometry. Though bad welds will affect the expected life of any pig, the effect will be far less on a dynamic one when compared to other static, over-measured pig designs. LIAG® pigs are highly flexible and suited for tight radii (R = 1.5 x D). As an option, dynamic lip pigs are equipped with a magnet for location and control. They are FDA-rated, formed from surgical-grade silicone, and available in the nominal widths DN 40 – 100 (1.5” – 4”)

Although hygienic pigging systems can be simple to add to food, beverage, and personal care processes, understanding the special considerations needed will help ensure your pigging procedure meets your desired outcome including:

There are additional factors to take into consideration when building your pigging system. Consult a pigging procedure expert to discuss pigging system automation, existing services to propel the pig, and special product considerations. Contact a Rodem representative to start building your hygienic pigging system and start capitalizing on the abundant savings possible by incorporating a pigging procedure into your food, beverage, or personal care process today!

E-mail: [email protected]

Copyright 2024 Rodem Inc. All rights reserved.