Reduce Product Waste with Anderson-Negele Turbidity Meters

With continually dwindling profit margins facing producers year after year, the need to reduce product waste is a reality. If you are using sight or time controlled methods for changeovers, you’re losing money.

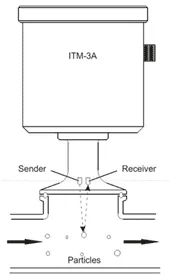

The Anderson Instrument ITM-3 turbidity sensor can automatically trigger the optimum transition point with extreme reliability and precision in contrast to alternative methods. Timing and sight methods are prone to error due to a number of variables. The result of using turbidity for transitions is a secure and reliable changeover without product loss.

How It Works

Rodem’s partner, Anderson Instrument defines turbidity as “the phenomenon where by a specific portion of a light beam passing through a liquid medium is reflected by undissolved particles. The sensor measures the light that is reflected by these particles to determine their concentration in the liquid.” For example, purified water would have nearly zero undissolved particles, while ice cream mix has a high concentration.

An inline turbidity sensor can be installed at leverage points in the process to facilitate instant detection of the following phase changes:

- Product-to-Product

- Product-to-Water

- Water to Cleaning Agent

The turbidity sensor allows immediate and accurate monitoring of product changeovers or CIP programs. The turbidity sensor can detect the instant a liquid media reaches a pre-defined specification. Producers have realized significant savings as a result of the turbidity technology, not only with reduced product waste, but also improved production efficiency, less chemical use, reduced utility costs and more.

Built for the stringent demands of sanitary processing, the stainless-steel sensor resists corrosion and offers high quality construction to ensure a long product life and extended precise performance.

Talk to a Rodem rep today and see how the Anderson ITM-3 can help cut your product waste and add to your bottom line.