Turbidity, the measure of suspended solids in liquids, is utilized as a measure of water quality and can be leveraged as a way for processors to slash waste, improve sustainability and control consumables. Turbidity Meters are engineered to detect the instant a liquid media reaches a pre-defined specification.

As concerns about the impact of industries on the environment grow, turbidity sensors are an ideal way to reduce waste and improve product yield. An inline turbidity meter should be installed at advantage points in the process to facilitate immediate detection of liquid media. Application examples for turbidity meters include:

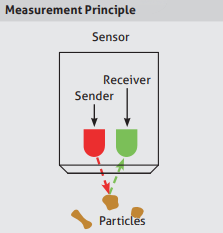

With the use of LED light sources, turbidity meters determine the level of particulate matter in water or other fluids. Anderson-Negele, our turbidity partner, defines turbidity as “the phenomenon where by a specific portion of a light beam passing through a liquid medium is reflected by undissolved particles. The sensor measures the light that is reflected by these particles to determine their concentration in the liquid.” For example, purified water would have nearly zero undissolved particles, while ice cream mix has a high concentration.

An infrared diode irradiates infrared light into the media. Particles in the media reflect the irradiated light which is detected by the receiver diode (backscatter principle). The electronics calculate the relative turbidity of the media according to the received signal.

Turbidity Meter Options

Our turbidity partner, Anderson-Negele’s sensors are designed and suitable for inline turbidity measurement. The four-beam turbidity meter is specifically designed to meet the requirements of the fluid food and beverage industries. Sanitary by design, Anderson-Negele turbidity meters meet the highest expectations of accuracy, durability, and cleanability.

For high turbidity applications typically found in dairy processing, the ITM-51 Turbidity Meter proves to be a cost-effective insertion sensor for:

When low turbidity measurement is needed, the ITM-4 4-beam Turbidity Sensor provides the needed resolution for (COW) water reuse, chill media monitoring and other high purity applications.

Turbidity meters are a simple and affordable way to generate big payback for your process. From reducing CIP consumables to boosting yield through improved changeovers, turbidity meters are an ideal option for sustainability-minded producers. For more information of how to integrate turbidity meters into your process or get more info on calculating potential ROI, contact a Rodem rep today.

E-mail: [email protected]

Copyright 2024 Rodem Inc. All rights reserved.