Positive Displacement Pumps Vs. Centrifugal Pumps: Which is Right for Your Sanitary Process

The centrifugal pump is the most commonly used pump type in the world, but it may not be the most suitable for your sanitary processes.

Rodem is dedicated to supporting the essential industries we serve. Not only does our team stand ready to roll up our sleeves to help trouble-shoot a tricky processing problem or to execute a complicated installation during a tight shut-down schedule, we empower our customers through valuable educational resources at their fingertips.

Check out our Blog section to find educational content, stay on top of the latest industry trends, discover new products, explore proven solutions, see Rodem at work and more.

The centrifugal pump is the most commonly used pump type in the world, but it may not be the most suitable for your sanitary processes.

Air operated double diaphragm pumps (AODD) are a great option for transfer applications thanks to their simple design that makes operation simple and repairs cost effective.

If you are considering enhancing or introducing CIP or COP procedures or equipment into your plant it is vital to have a complete understanding in order to take full advantage of these processes.

Sanitary centrifugal pumps are the most common type of process pumps used in the sanitary processing industry, and for good reason. Learn about the major benefits these pumps provide and why it could be the best solution for your processing application.

Ampco’s ZP Series circumferential piston pumps provide standard features and material upgrades that add to the durability of these workhorse pumps.

Ampco’s high efficiency centrifugal LC, LF and LD pump lines are functionally and hydraulically identical to Fristam’s FPX, FPR and FP models.

Stop flushing valuable product caught within your pipe or tubing system! Pigging systems can be used to recover up to 99% of this product helping you recapture usable product and drastically cut down on waste. Learn how this system works and if it the right solution for your application.

Learn about how twin screw pumps can be used in the dairy, food & beverage and personal care & pharmaceutical industries, and the benefits and applications in each industry.

Twin screw pumps offer precise tolerances and the ability to pump a wide range of viscosities and temperatures, partnered with an extremely low cost of ownership make twin screw pumps a top choice for sanitary processors in food, beverage, personal care and other high purity industries.

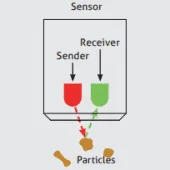

Learn about how exactly a turbidity meter works, the benefits it offers, and why it might be the perfect solution for your sanitary processing applications.